June 5th - June 6th, 2019

Telč, Czech Republic

| Jonathan Glinz | |

| Upper Austria University of Applied Sciences Wels | |

| Jonathan Glinz received his MSc degree in Healthcare and Rehabilitation Technology at the University of Applied Sciences Technikum Wien (Austria). In 2017 he started to work as a research associate at the Research Group Computed Tomography of the University of Applied Sciences Upper Austria (Campus Wels). His research interests are the three-dimensional characterization of micro structures in biomedical and additively manufactured materials using X-ray microcomputed tomography. |

Investigation of additively manufactured titanium parts using micro computed tomography | |

Jonathan Glinz | |

|

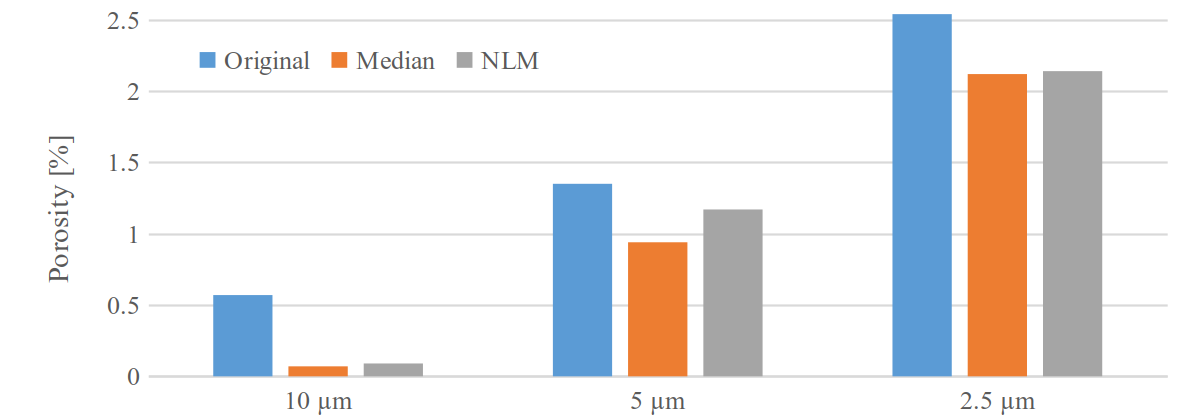

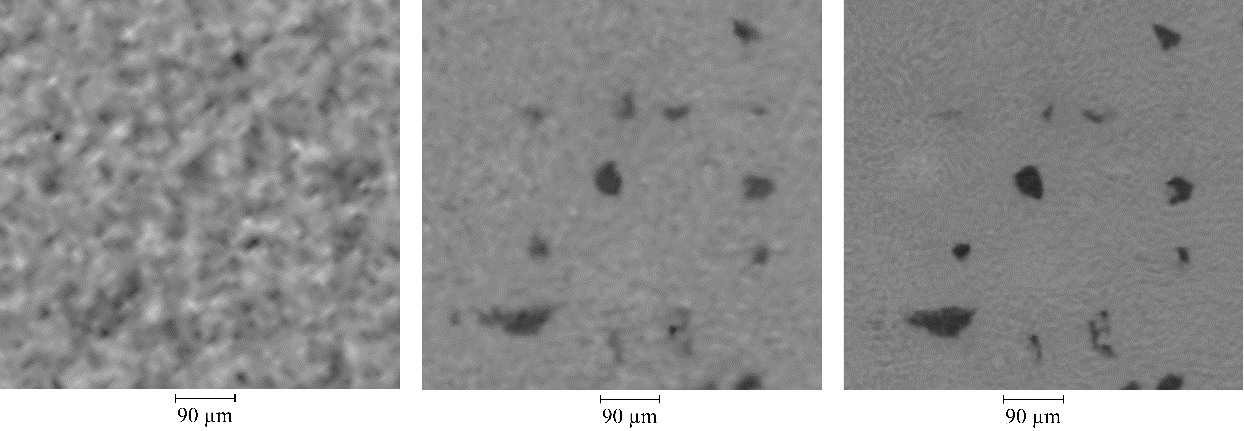

Components manufactured from titanium alloys are the state-of-the-art solution for all kinds of medical implants and prostheses due to their high strength and biocompatibility. Furthermore, components of high complexity can be produced via additive manufacturing (AM), which allows for more flexibility and easy prototyping of patient specific implants. However, this flexibility implies the risk of internal defects resulting from the manufacturing process. The nondestructive investigation of critical components is therefore crucial to avoid premature failure. With X-ray micro-computed tomography (XCT) internal structures such as pores, cracks or inclusions of unwanted material can be resolved three dimensionally in a non-destructive way. While the investigation of additively manufactured titanium components via XCT is promising, it can be challenging to achieve the best possible image quality. For that reason, scan parameters such as voxel size, tube voltage and current as well as applied pre-filtering and post-processing steps need to be optimized. In this contribution, we will discuss the influences of scan parameters on image quality and resulting porosity values in additively manufactured Ti6Al4V components. For this purpose, image quality parameters such as contrast to noise ratio (CNR) and slanted-edge modulation transfer function (MTF) according to ISO 12233 are determined and compared. Results show that tube voltage and current greatly influence the CNR of the data set while the MTF is, within limits, almost constant as long as the electron beam focus is optimized. With higher physical resolution, smaller defects can be detected, which leads to increasing porosity values at 10, 5 and 2.5 µm resolution respectively (see Figures 1 and 2). Image post-processing can further influence porosity outcome because of the segmentation of noise-induced particles. Different image denoising algorithms therefore strongly reduce porosity values depending on spatial resolution. | |

Figure 1: Evaluated total porosity of an AM Ti6Al4V specimen at 10, 5, and 2.5 µm voxel size, without post-processing (blue) and with median (orange) and non-local means filter (grey) applied. |

|

Figure 2: Average pore (diameter of 72 µm ) in an AM Ti6Al4V specimen at 10, 5, and 2.5 µm voxel size from left to right. |

|